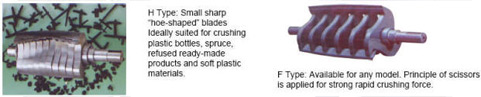

Extrusion Blow Mold >> GRINDERS/GRANULATORS

WHICH GRINDER/GRANULATOR?

MODEL CHOICE CHART

| Type |

Main Usage |

| D | American general purpose grinder for bottles (Handles all Can Mold molder output). |

| BD | Like “D” type, but oversize (Large bottles or accumulator head output). |

| SS & R | For pre-forms (Makers of pre-forms). |

| SH | Very difficult, hard or rigid blow molded plastics. |

| Y | Polycarbonate bottles. |

| YN | Same as "y" type, but lots of upgrades, including lower noise and stainless steel upper in-feed sector. |

"GENERAL PURPOSE PLASTIC GRANULATORS"

D Type: An American style granulator with double walls to reduce noise. The base frame is made of steel to prevent cracking. It can be installed with an A style "Scissors shaped" blade or a C style "Claw blade". The blades are made of a strong steel, to ensure effective operation. It can be operated with a suction motor for automatic production, or a water-cooling system can be added if long periods of operation are required.

The above data is for a 20 gram preform. Data varies with each mold according to preform requirements. Standard S136 stainless steel is used and heat treated to HRC 45°– 48° C. Each cavity has its own PID temperature controller.

"LARGE SIZE GRANULATORS"

Pet All’s large & powerful granulators with low noise are designed for crushing larger plastic products, such as TV cases, automotive resin and collections of scrap for recycling. Moderate speed motors are used for larger models as they create less noise. It can be operated with an auto-loader, as well as with automatic conveyors. Sliding wheels are installed under the upper hopper for safety and ease of cleaning.

|

FEATURES: • Suitable for crushing refused scraps for recycling by the application in factories. • Casing is made of stainless steel, hermetic designed with double layer for sound proofing. • Elegant blades made of chrome steel from Europe. • Blades are designed in V type for extremely powerful crushing. • Electrical components are made in Japan and Europe. • The upper hopper is equipped with sliding wheels for easy opening. • The upper hopper is also equipped with a hydraulic damper which is controlled electrically. |

|

|

"Fully equipped JUMBO SIZE Grinder with Loading"

| "PRE-FORM GRANULATORS" | |

|

SS Type: Compact auxiliary granulator, designed with rolling granulating blades, rotation speed (36-60 RPM), and generates ultra low noise. The SS type can be operated with an auto-loader, suction motor loader and even works together with robots. |

| "HARD PLASTIC GRANULATORS" | ||

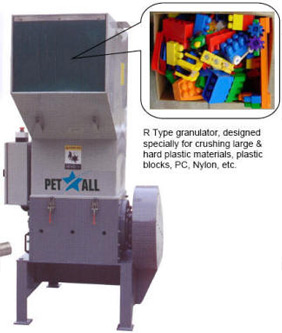

| R Type: This kind of crusher is specially designed to crush big and hard plastic materials, such as plastic blocks, PC and Nylon. If long term operation is required E type claw blades are recommended with a water-cooling system. Small sized claw blades can be used with all granulators, divided into rotary blade, applied with the principle of scissors, for crushing any hard plastic materials. The blades are made with imported European special blade steel, |  |

“HARD/DIFFICULT PLASTIC GRANULATORS”

PET ALL has accumulated more than 15 years of experience in er="1" />

“COMPACT HARD MATERIAL GRANULATORS”

Y Type: Practical granulator finished with stainless steel base casing to prevent cracking. It can be installed with A-Plain blade or C-Claw blade. Made of special granulating blade steel.

YN Type granulator’s functions are similar to the Y-Type granulators. Designed with stainless steel upper hopper to reduce noise creation. Elegant design that creates low noise.

UK & Europe Hotline:

Canadian Head Office:

ADDRESS:

85 Royal Crest Court

Markham, Ontario

L3R 9X5

Canada

TELEPHONE:

905-305-1797

FAX:

905-305-0013

E-MAIL:

obrandau@petallmfg.com

Pet All DEMONSTRATION CENTER

620 Minnie Street

Paynesville MN 56362

TELEPHONE:

905-305-1797

E-MAIL:

obrandau@petallmfg.com

China Centre:

TELEPHONE:

86 139 624 78740

WeChat ID:

13962478740

E-MAIL: liulvkuan@163.com