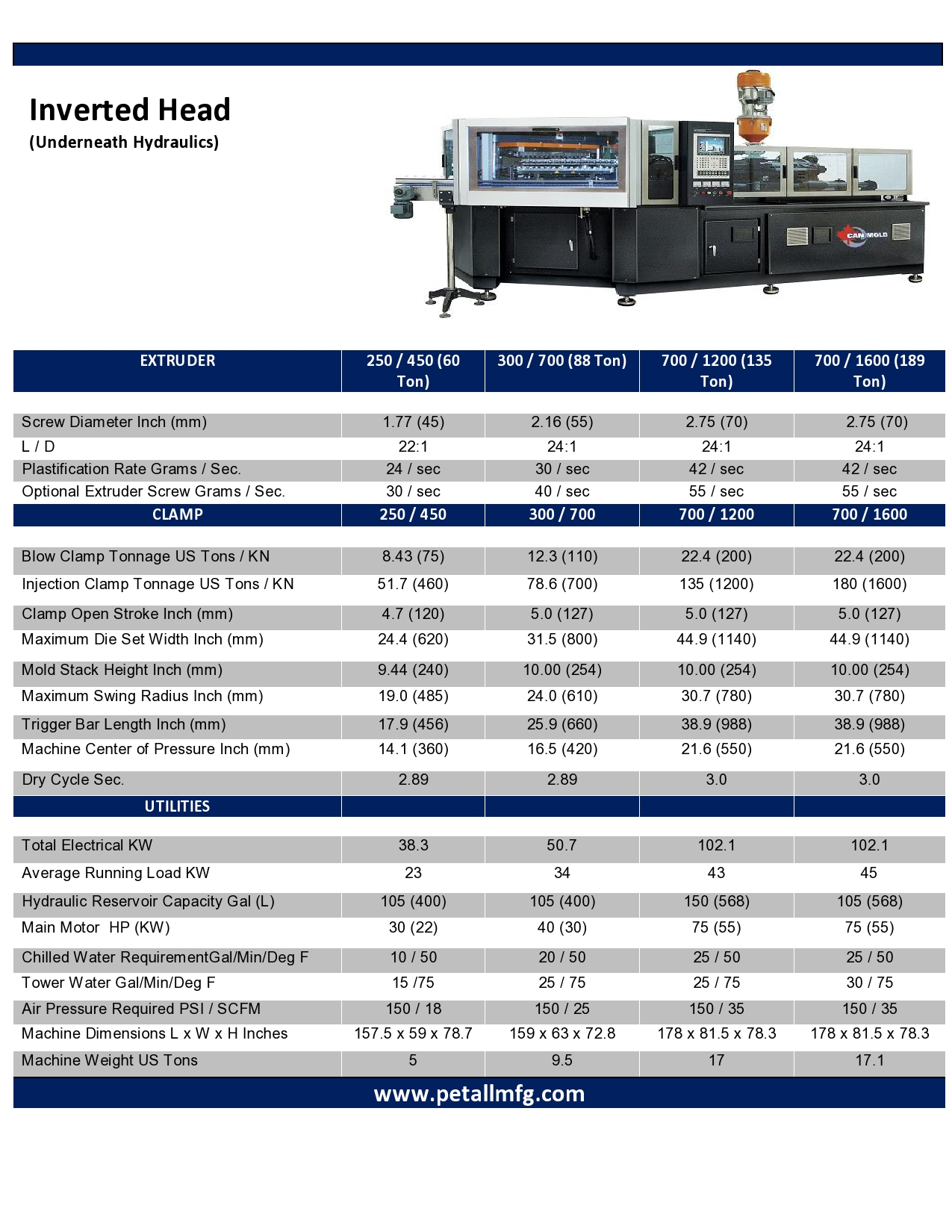

Products >> IBM (Injection Blow Molding) >> Inverted Head

VIDEO - "IBM Inverted Head - 88 Ton (300-700) with Leak Detector"

DESCRIPTION: 4 standard models represent the most advanced design of equipment to produce clean, contamination free parts which are ideal for the pharmaceutical, medical, food and cosmetic markets. All parts that can leak oil or hydraulic fluids are located below the mold area to avoid mold and container contamination from above.

The CAN MOLD machine has features unavailable from competitors, offering both:

- reciprocating screw and

- continuous extrusion options in the same machine.

MODELS:

4 standard models are available:

- IBM 250/450 (60 Ton)

- IBM 300/700 (88 Ton)

- IBM 700/1200 (135 Ton)

- Model 700/1600 (189 Ton)

FEATURES:

- Inverted Head - oil and hydraulic components below mold area

- Special "O" Ring sealed hydraulics

- Heavy duty, vibration free, stable design

- Advanced B&R (Austrian) PC based control; touch tone with color displays

- OSHA type 360° guarding around whole machine, not just mold area

- Completely automatic system with discharge and take-away conveyor

- Optional high speed integrated leak detector system

- Exclusive, unique reciprocating screw as well as continuous extrusion in the same machine

- Swing out, quick change screw design

- Very high speed cycle times

- Extremely low amperage draw compared with equivalent competitors' models (IBM 300/700 model 55 amps average draw)

COMPONENTS:

Components have been specially selected for their commercial availability in North America and Europe. Electrical components are selected to meet SEC 70 North America), CE (European ) and Canadian (Ontario and Quebec) directives.

MAJOR COMPONENT SUPPLIERS ARE:

- FESTO Pneumatic System (Germany)

- YUKEN Hydraulics (Japan)

- PARKER high pressure pipes and hoses (Germany)

- B&R advanced PC based control system (Austria)

Low Energy Consumption:

IBM 300/700 connected load is 88 amps, but average usage is a mere 55 amps. Cost per month in energy is about US $1950, compared with US $4000 from our competitor's equivalent model, which requires a 200 amp connected load. The differential exists across all models.

Mold Size Capabilities (mm) IBM 300/700 Models

Other sizes available on request. Product drawings or a bottle sample will be required for final configuration.

| Bottle | Neck "T" mm | Height "H" mm | Diameter O/dia mm | Cavities | Center Distance | |

| A | 5 ml | 10 | 35 | 15 | ||

| B | 10 ml | 15 | 40 | 20 | 20 | 35 |

| C | 20 ml | 15 | 50 | 25 | 18 | 40 |

| D | 30 ml | 20 | 60 | 30 | 16 | 42 |

| E | 40 ml | 22 | 65 | 35 | 14 | 45 |

| F | 60 ml | 28 | 75 | 40 | 13 | 50 |

| G | 80 ml | 30 | 80 | 45 | 12 | 55 |

| H | 100 ml | 32 | 85 | 50 | 12 | 60 |

| I | 150 ml | 35 | 90 | 53 | 10 | 70 |

| J | 200 ml | 38 | 100 | 58 | 8 | 85 |

| K | 400 ml | 42 | 120 | 65 | 6 | 110 |

| L | 650 ml | 50 | 160 | 80 | 5 | 120 |

| M | 1000 ml | 40 | 200 | 90 | 4 | 150 |

| N | 1500 ml | 45 | 200 | 100 | 3 | 180 |

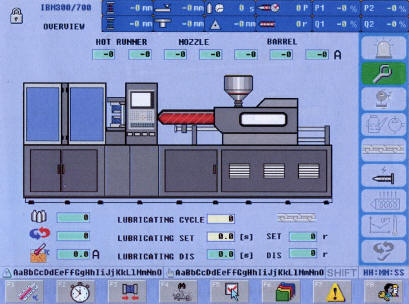

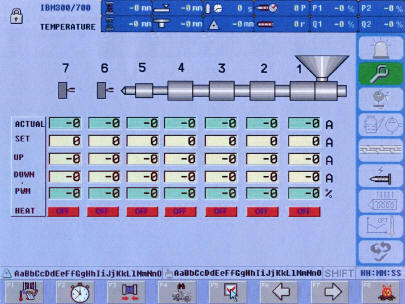

Touch Screen Controls:

Superb, bright color monitor covers all aspects of the machine. Below are 2 screen examples

Overview page (Fig. 7-10)

Screw temperature page (Fig. 7-11)

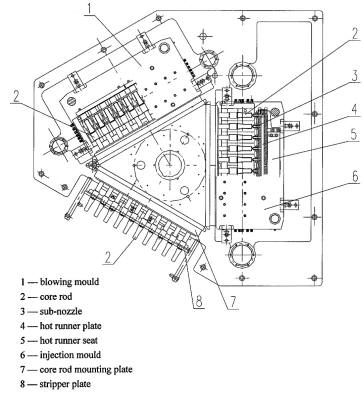

Mold Sets:

Molds of the very highest quality are provided with the machine or sold as separate items. Tools interchangeable with Jomar and Uniloy IBM equipment are available as standard. Molds are produced in both high quality alloys or stainless steel.

A set of molds is made up as follows:

Support:

- Parts are available from our North American distribution/offices and from Pet All Manufacturing Inc., Markham, Ontario, Canada facilities.

- Technical support is available from Toronto, Michigan (USA) and Manchester (UK).

- Training school and pre-delivery instructions are recommended in Toronto or Manchester (UK).

- Integrated support equipment is available for turnkey facilities (high speed leak detectors, temperature control units, tooling, feeding, conveyors)

- Superb user's manual, parts manual, services manual are standard with the machine.

UK & Europe Hotline:

Canadian Head Office:

ADDRESS:

85 Royal Crest Court

Markham, Ontario

L3R 9X5

Canada

TELEPHONE:

905-305-1797

FAX:

905-305-0013

E-MAIL:

obrandau@petallmfg.com

Pet All DEMONSTRATION CENTER

620 Minnie Street

Paynesville MN 56362

TELEPHONE:

905-305-1797

E-MAIL:

obrandau@petallmfg.com

China Centre:

Mike Liu

TELEPHONE:

86 139 624 78740

WeChat ID:

13962478740

E-MAIL: liulvkuan@163.com